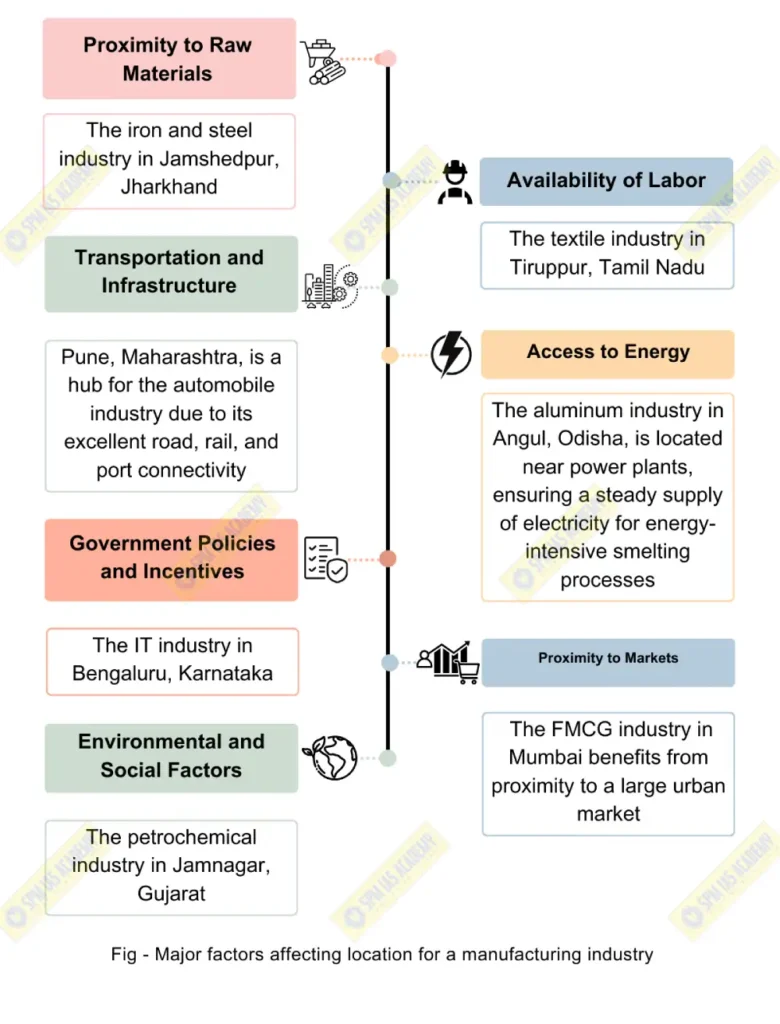

The selection of a location for a manufacturing industry is influenced by several critical factors, each contributing to operational efficiency, cost minimization, and market access. Below are the major factors :

1. Proximity to Raw Materials

Importance: Industries reliant on bulky or perishable raw materials often locate near these sources to reduce transportation costs.

Example: The iron and steel industry in Jamshedpur, Jharkhand, is situated near iron ore and coal mines, minimizing the cost of transporting heavy raw materials.

2. Availability of Labor

Importance: Access to skilled or inexpensive labor is crucial for industries, especially those that are labor intensive.

Example: The textile industry in Tiruppur, Tamil Nadu, thrives due to the availability of skilled textile workers, essential for maintaining high productivity.

3. Transportation and Infrastructure

Importance: Efficient transportation networks reduce the cost and time of moving goods and materials.

Example: Pune, Maharashtra, is a hub for the automobile industry due to its excellent road, rail, and port connectivity, facilitating the efficient distribution of vehicles.

4. Access to Energy

Importance: Energy-intensive industries require a reliable and affordable energy supply to sustain operations.

Example: The aluminum industry in Angul, Odisha, is located near power plants, ensuring a steady supply of electricity for energy-intensive smelting processes.

5. Government Policies and Incentives

Importance: Favorable policies, including tax incentives and subsidies, attract industries to specific locations.

Example: The IT industry in Bengaluru, Karnataka, flourished due to supportive government policies and the establishment of technology parks.

6. Proximity to Markets

Importance: Being close to markets reduces distribution costs and improves response times, which is crucial for industries dealing in perishable or high-demand consumer goods.

Example: The FMCG industry in Mumbai benefits from proximity to a large urban market, enabling companies like Hindustan Unilever to minimize logistics costs and swiftly meet consumer demand.

7. Environmental and Social Factors

Importance: Environmental regulations and community relations can influence location choices, especially for industries with significant environmental impacts.

Example: The petrochemical industry in Jamnagar, Gujarat, benefits from favorable environmental policies and established industrial infrastructure.

Role of Market in the Selection of Location

Market proximity is a critical factor in determining the location of manufacturing industries, particularly those involved in the production of consumer goods, perishable items, or goods requiring rapid delivery. Being close to the market reduces transportation costs, allows for quicker response to customer demands, and improves the efficiency of distribution networks.

- Example of the FMCG Industry: Fast-Moving Consumer Goods (FMCG) companies, such as Hindustan Unilever and ITC, strategically locate their manufacturing units close to urban centers and major consumer markets. This proximity enables them to distribute products swiftly, meet consumer demand, and maintain competitive pricing by minimizing logistics costs.

- Example of the Automobile Industry: As mentioned earlier, the automobile industry in Gurgaon, Haryana, benefits from its proximity to the Delhi-NCR market. Being close to a large and affluent consumer base allows automobile manufacturers to supply vehicles more efficiently and manage their supply chains effectively.

- Example of the Food Processing Industry: Food processing units often locate near urban markets to ensure the freshness of perishable products. The dairy industry in Gujarat, with brands like Amul, benefits from its proximity to both rural suppliers and urban consumers, ensuring timely processing and distribution of dairy products.

Relevant Theory: Weber’s Least Cost Theory

Alfred Weber’s Least Cost Theory emphasizes that the optimal location for a manufacturing

industry is where the costs of transportation, labor, and agglomeration are minimized. According

to this theory, if the final product is heavier or bulkier than the raw materials, the industry should

locate closer to the market to minimize transportation costs.

Example in Assam: The tea industry in Assam, particularly in regions like Dibrugarh and Jorhat, reflects Weber’s theory in practice. The proximity to tea plantations (raw material) reduces initial transport costs, while the relatively closer proximity to major markets like Kolkata ensures that transportation costs for the final product are also minimized. Additionally, Assam’s connectivity via rail and road networks facilitates efficient distribution to markets across India and globally.

The selection of a manufacturing location is driven by factors like raw materials, labor, infrastructure, and government policies, with market proximity essential for reducing costs and enhancing competitiveness. As India advances towards Viksit Bharat, aligning industrial location decisions with these factors will be crucial for fostering sustainable growth, balanced regional development, and global market integration.

Check out UPSC Coaching Centre Guwahati | APSC Coaching Centre Guwahati | Crack APSC Exam | UPSC Civil Services Exam | Ethics Paper in UPSC Exams